Beverages Production System

- Raw Material Management

- Manufacturing Order Creation

- Packaging and Stock Management

- Quality Control and Standards

- Maintenance Tracking

- Waste Management

Explore How This Module Benefits Various Business Types

Inventory Control

Track and manage raw materials to prevent shortages and ensure smooth production.

Consistent Product Quality

Use BoM to maintain recipe consistency, ensuring high-quality batches every time.

Manufacturing and Packaging

Optimize production workflows, monitor equipment, and manage packaging for seamless distribution.

Raw Materials Management

Soft drink producers can efficiently track and manage ingredient stock levels, ensuring uninterrupted production.

Consistent Recipe Control

Using the BoM feature, producers maintain precise ingredient ratios for consistent flavor and quality across all batches.

Optimized Packaging

The module ensures proper labeling and packaging, streamlining the final steps before products hit the market.

Ingredient Tracking

Breweries and distilleries can manage grain, hops, and other raw materials, ensuring optimal stock levels for production.

Recipe Consistency

The BoM feature ensures precise ingredient measurements, maintaining consistency in each batch of beer or spirits.

Packaging Management

Streamline packaging processes, ensuring bottles and cans are labeled correctly and prepared for distribution efficiently.

Raw Material Management

Track ingredients like caffeine, taurine, and sugars, ensuring a consistent supply for production without interruptions.

Recipe Standardization

Use the Bill of Materials (BoM) to ensure exact ingredient ratios, maintaining flavor and quality consistency across every batch.

Production and Packaging

Monitor production timelines and streamline packaging, ensuring energy drinks are labeled, packaged, and ready for distribution on time.

Ingredient Tracking

Monitor and control dairy ingredients to avoid stock shortages and streamline production schedules.

Quality Assurance

Ensure consistent dairy product quality by using production monitoring tools and maintaining batch standards.

Production Process

Track production timelines and manage equipment use to improve operational efficiency in dairy manufacturing.

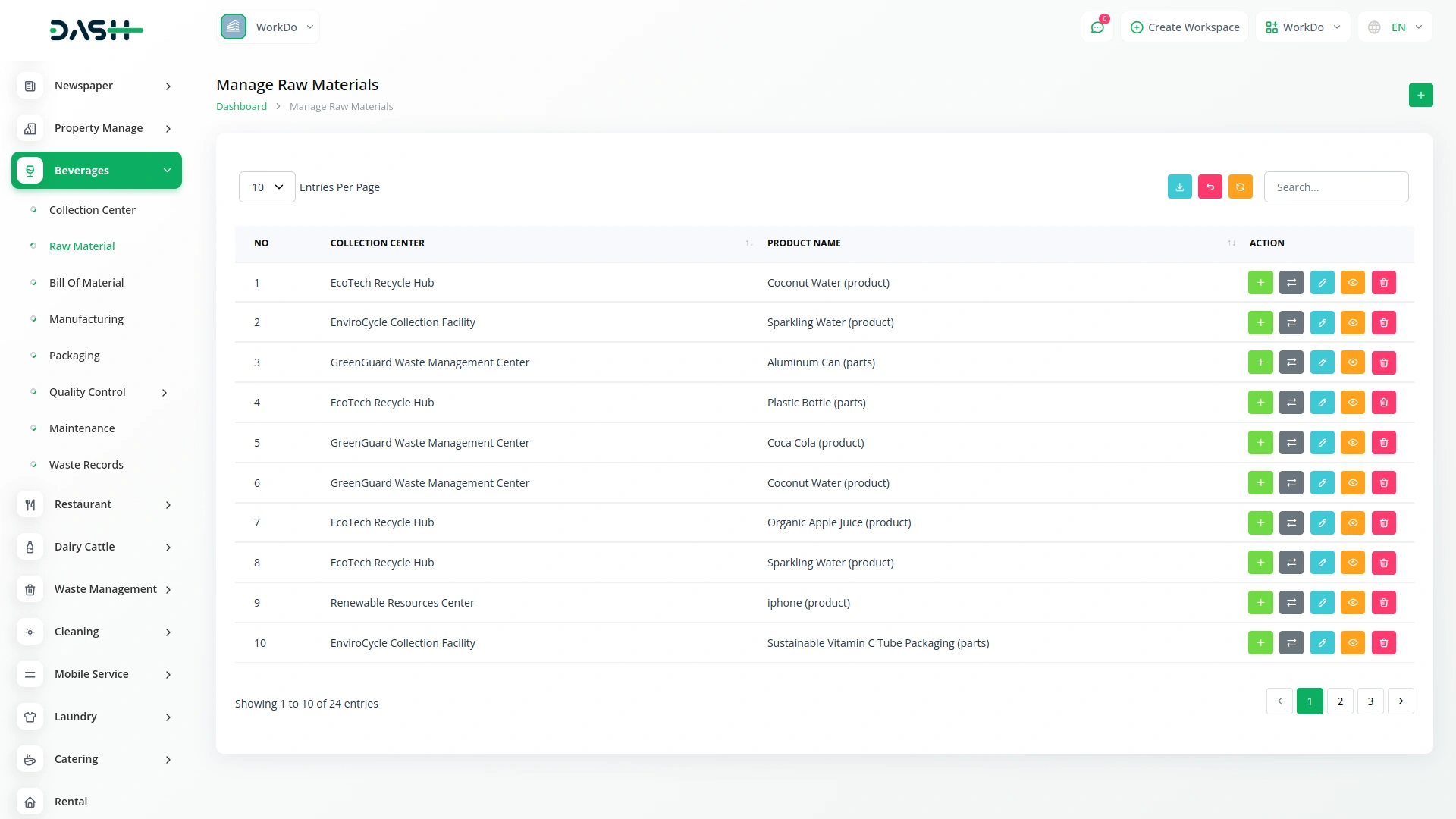

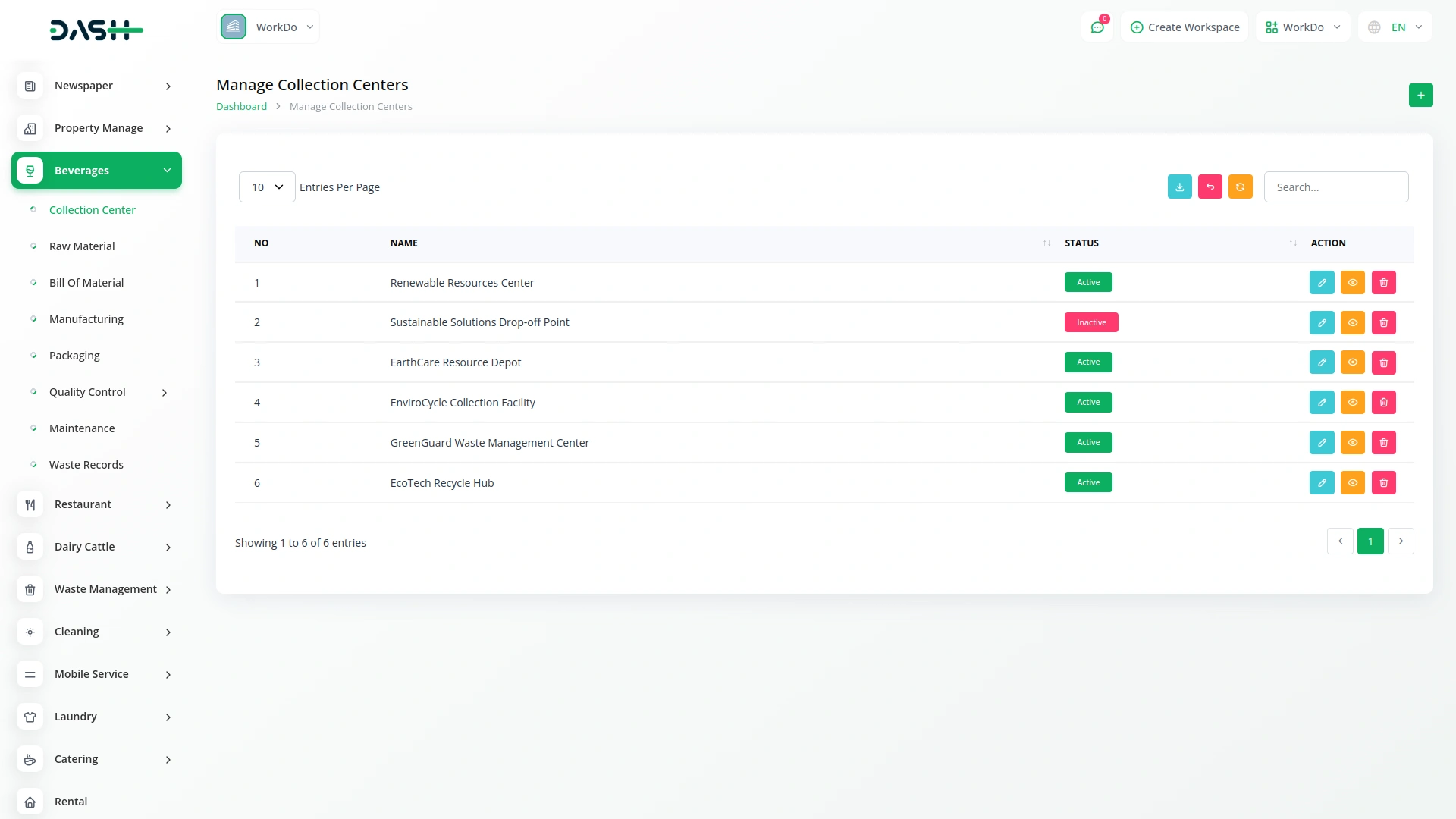

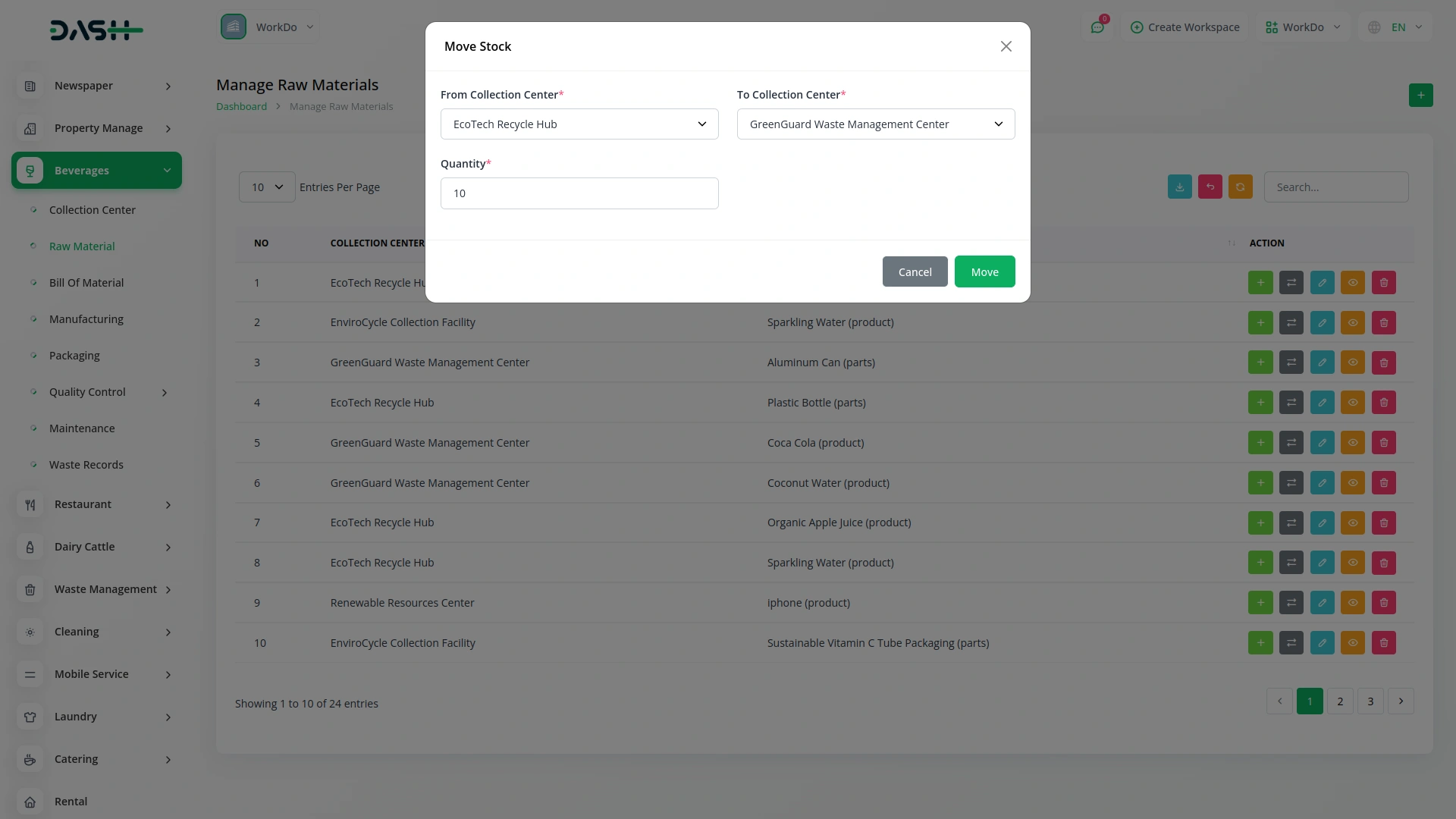

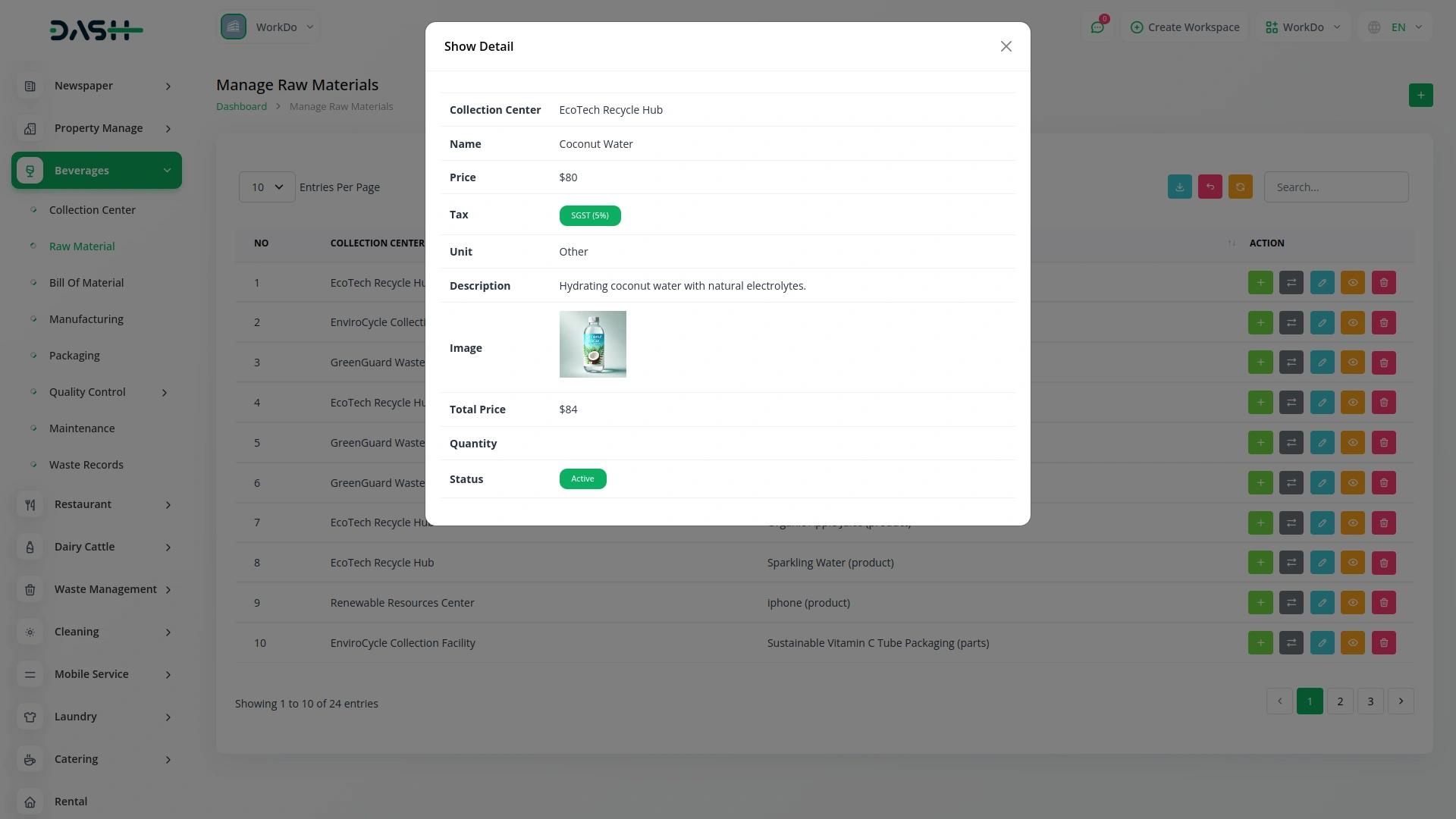

Raw Materials Control

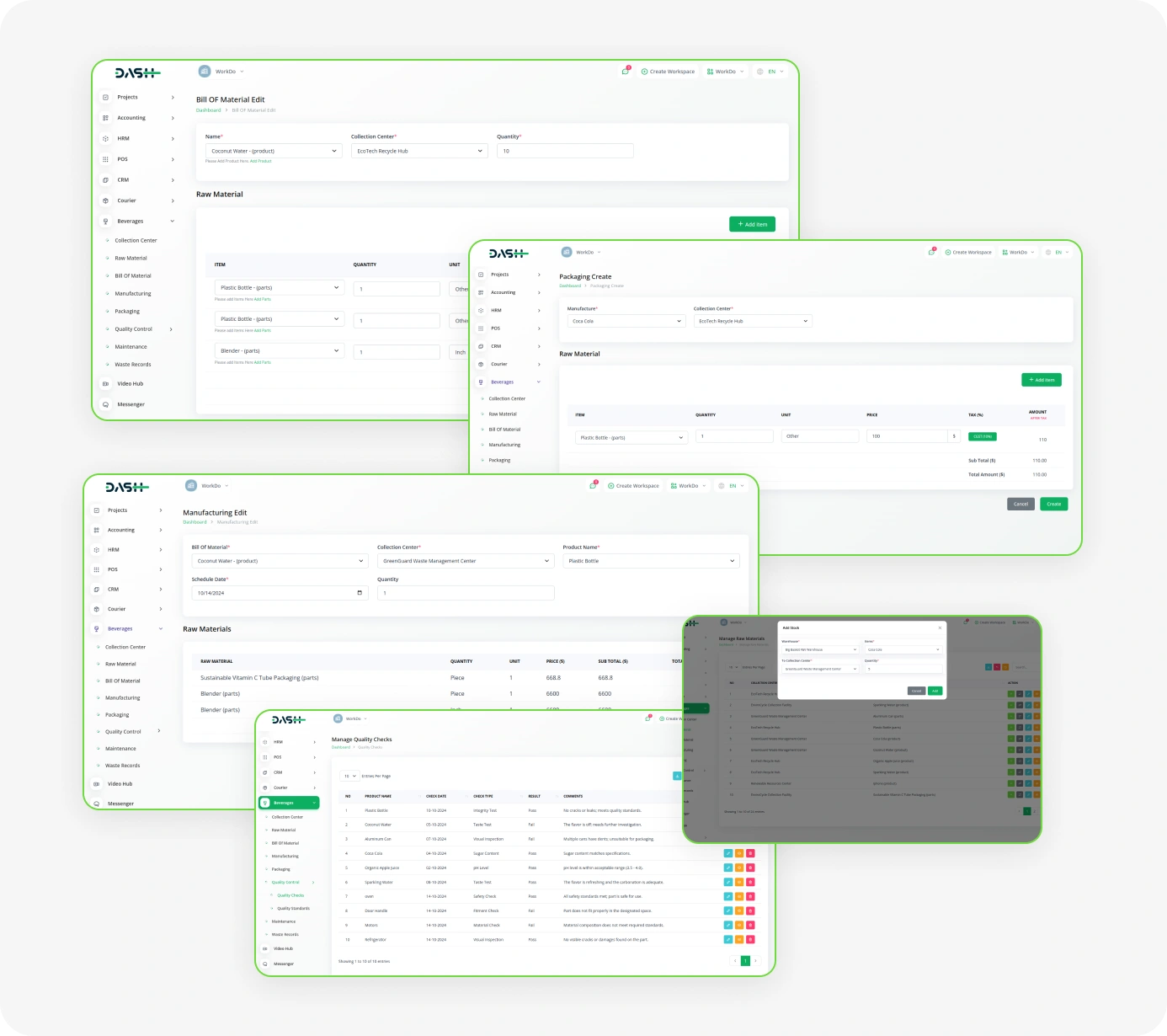

Streamline raw material operations through intelligent collection center selection and automated product/service item management with real-time inventory tracking capabilities. The system provides comprehensive auto-population of item details including specifications, pricing, taxation, units, and visual documentation while enabling dynamic status control for optimal availability management. Advanced stock management features facilitate seamless inter-center transfers, precise quantity tracking, and comprehensive audit trails through integrated view, edit, and delete functionalities.

- Add stock quantities for each collection center

- Seamlessly transfer stock between collection centers

- Perform view, edit, and delete actions with ease

- Real-time availability status management

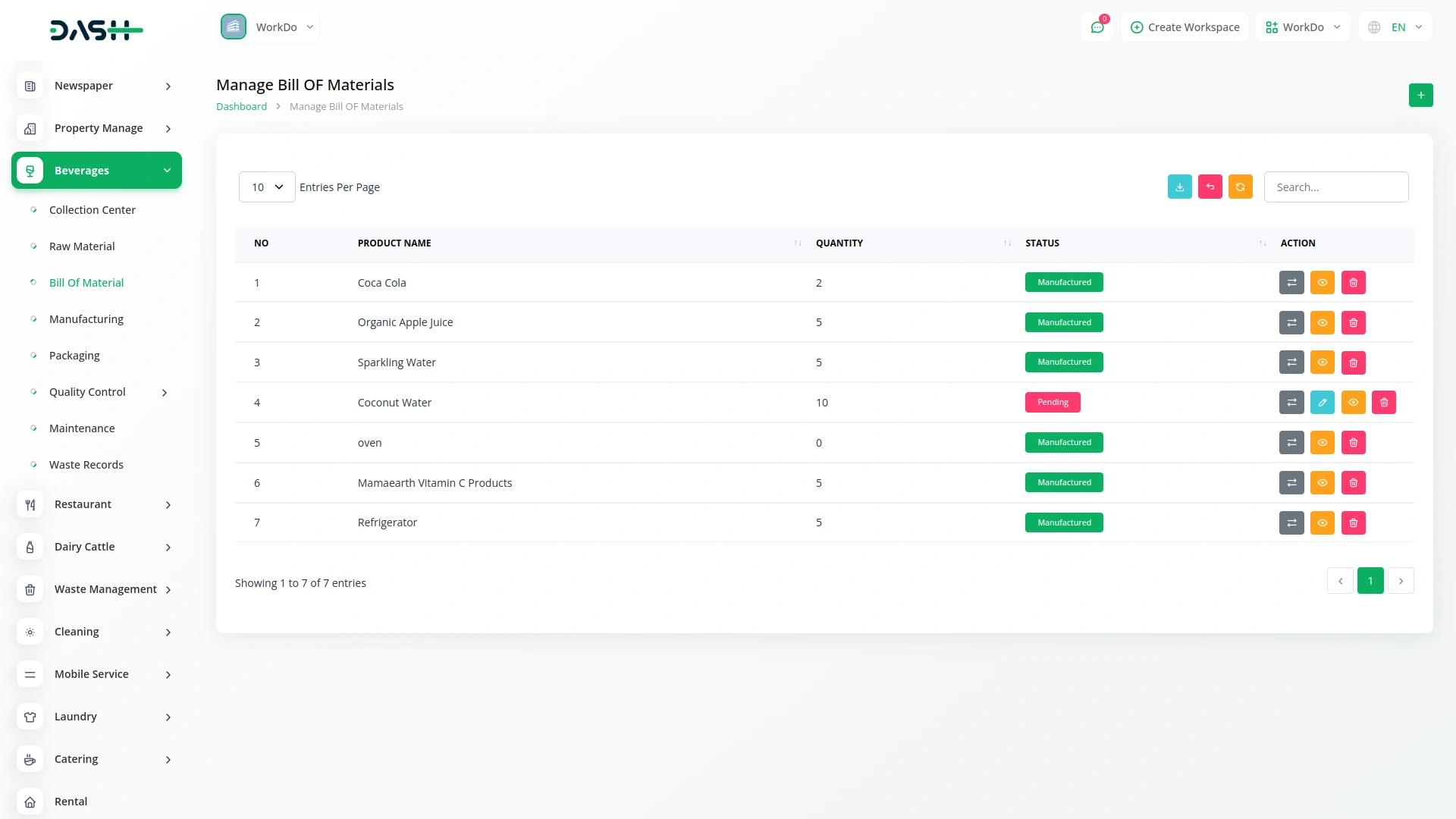

Bill of Materials Management

Optimize manufacturing resource allocation through sophisticated material requirement planning and comprehensive production cost analysis with automated calculation capabilities. This module enables precise specification of manufacturing quantities, detailed raw material listings with unit measurements, quantity requirements, individual pricing, and automatic subtotal computations while maintaining complete status tracking from pending through manufactured phases. The system incorporates advanced workflow management including stock movement controls, comprehensive viewing options, editing capabilities, and selective deletion functions.

- Add quantity to manufacture for each bill.

- Automated manufacturing quantity calculations and planning

- Intelligent material cost computation with real-time subtotals

- Comprehensive production cost analysis and reporting

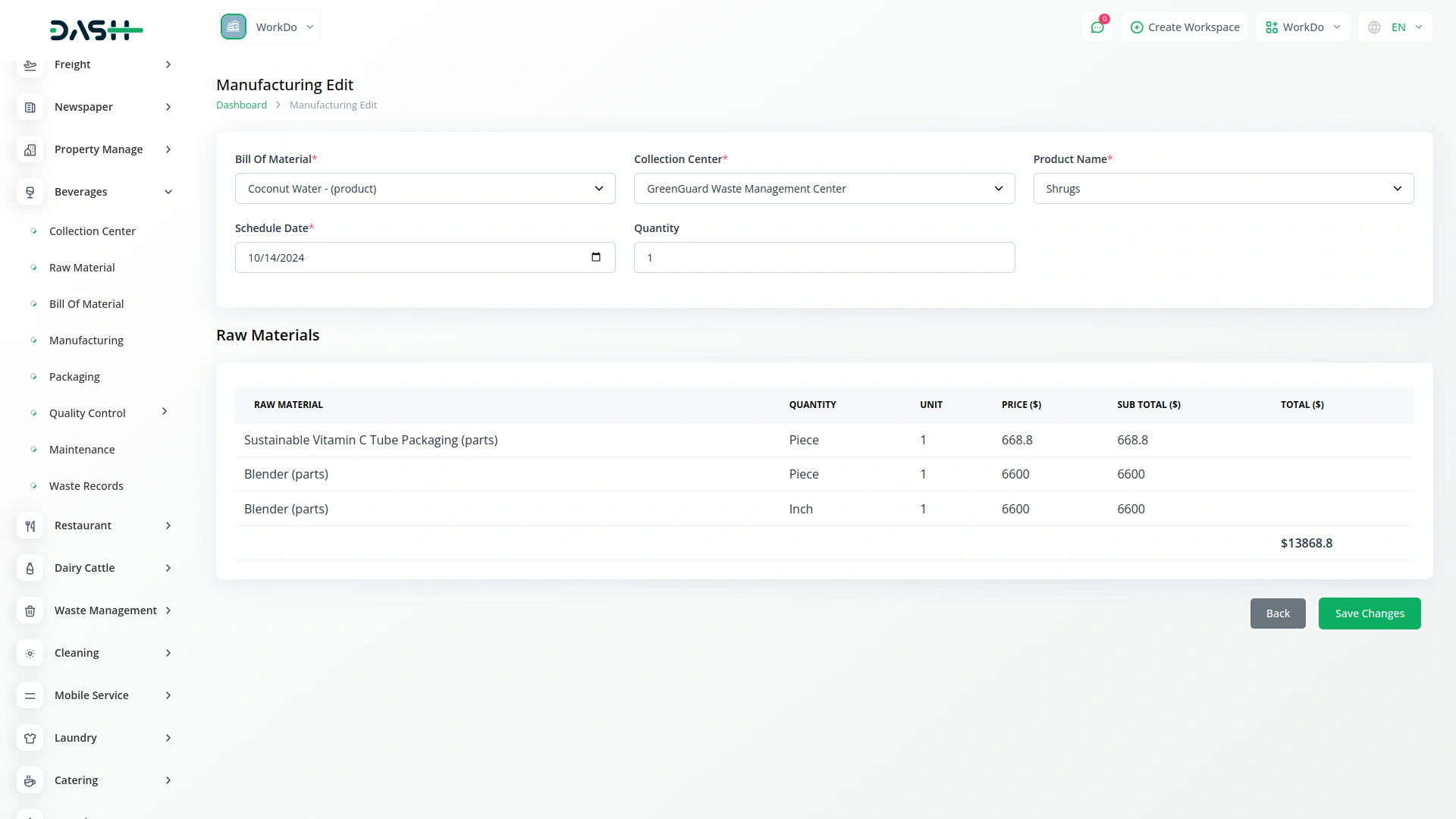

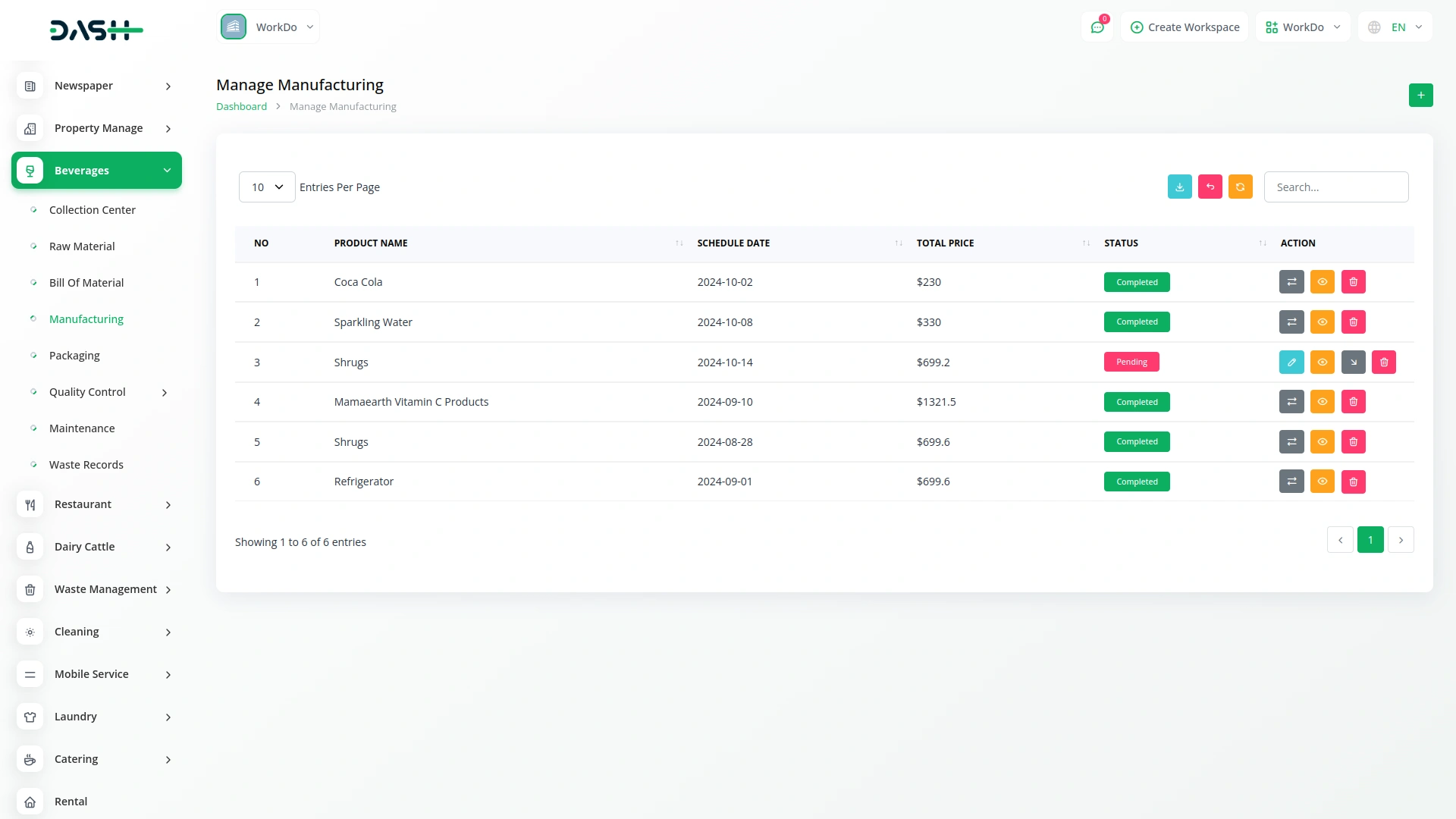

Manufacturing Order Creation

Revolutionize production initiation through streamlined order creation workflows that integrate Bill of Material selection, collection center assignment, and product/service specification with advanced scheduling capabilities. The system maintains intelligent status progression from initial pending state through completion with comprehensive editing controls that restrict modifications to pending orders while protecting completed manufacturing records. Enhanced functionality includes rapid order creation through essential detail entry, automated raw material selection based on BOM specifications, and strict edit controls ensuring data integrity.

- Rapid order creation with essential manufacturing detail integration

- Automated raw material selection based on BOM requirements

- Status-based editing controls with completion protection

- Comprehensive production scheduling and tracking

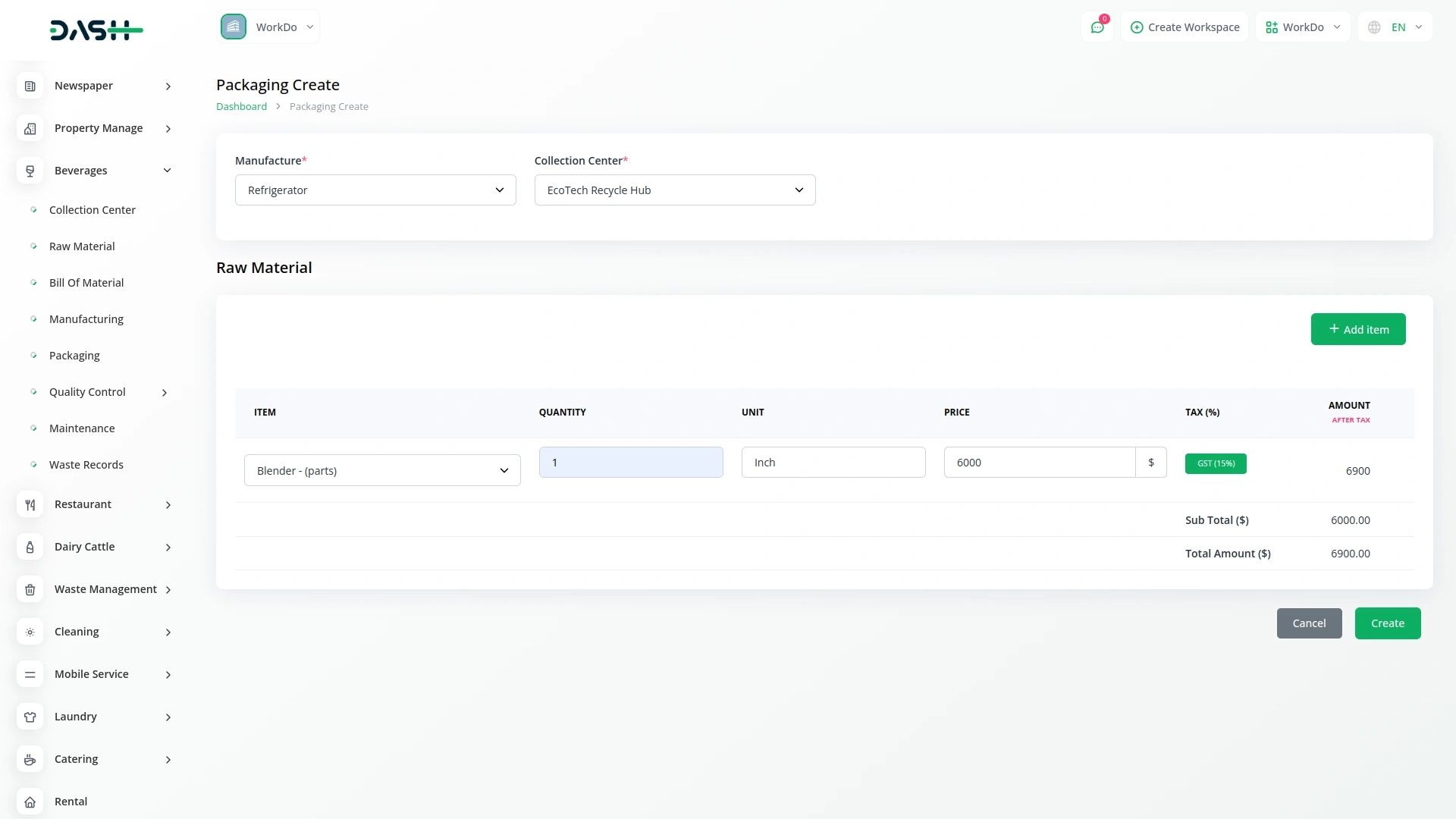

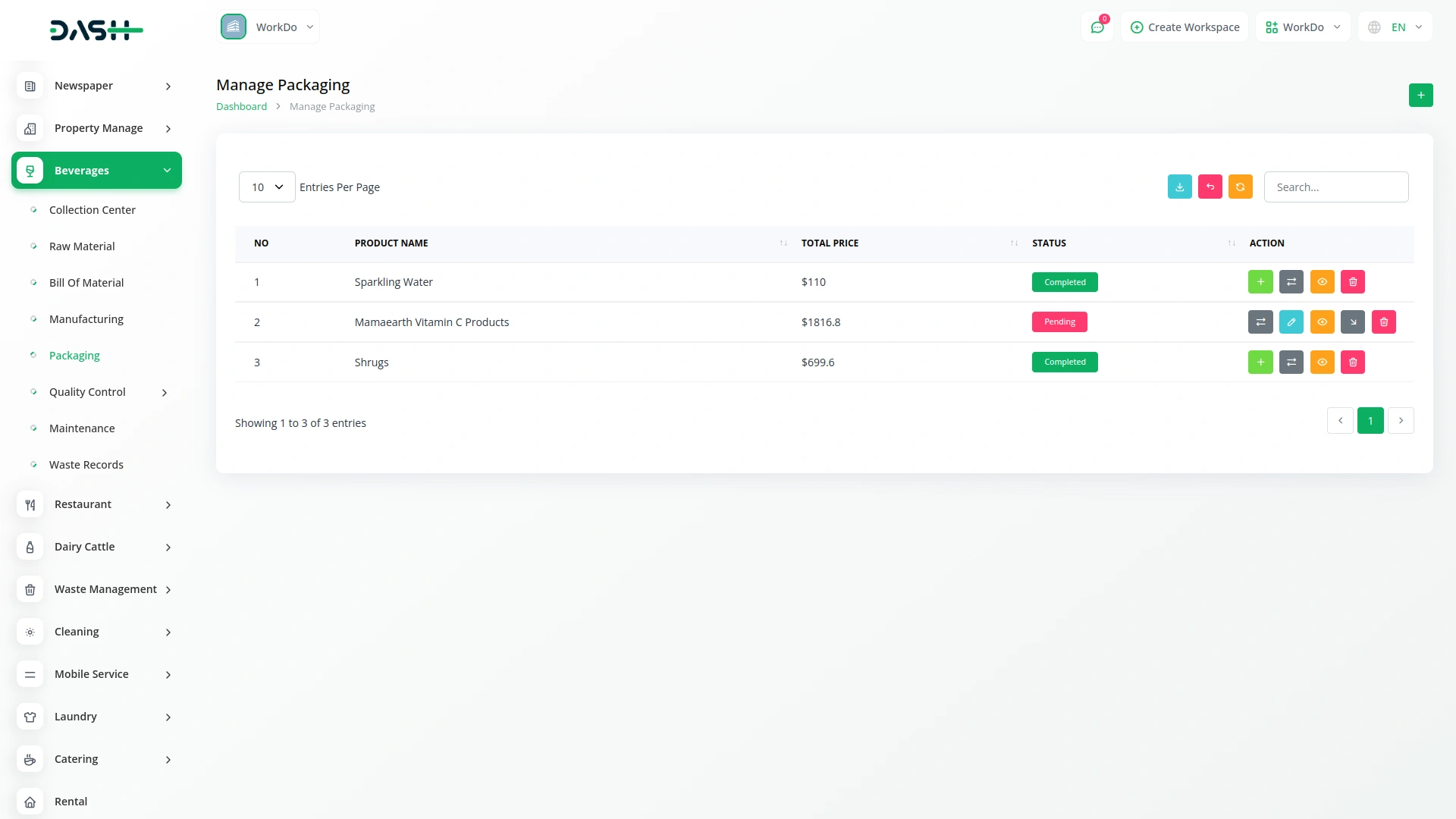

Packaging Process Overview

Enhance packaging operations through intelligent manufacturing order selection and automated collection center assignment with comprehensive material listing capabilities. The system automatically populates related raw material items including quantities, units, pricing, taxation, and total calculations ensuring accurate product accounting before distribution phases. Advanced status management initiates packaging records in pending state with comprehensive action controls for stock handling, inter-center movement, and completion status updates.

- Automated collection center inventory stock additions

- Seamless inter-center stock movement capabilities

- Intelligent status progression with completion validation

- Comprehensive packaging workflow tracking and management

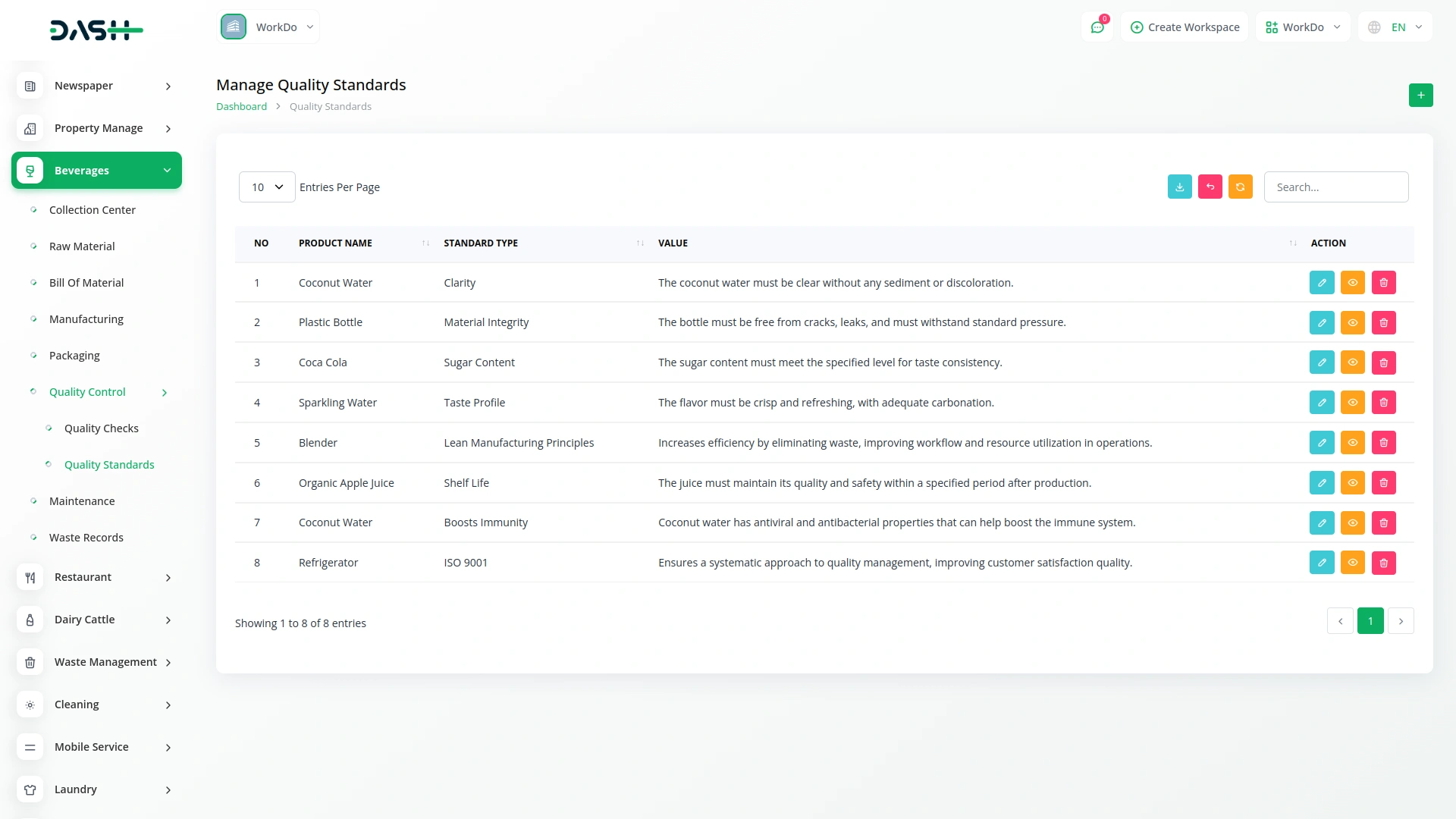

Quality Control & Checks

Implement rigorous quality assurance through comprehensive standard benchmark definition and systematic quality check protocols with detailed audit trail maintenance. The system enables categorized standard establishment by type and value specifications while facilitating regular quality assessments with result logging and detailed commentary tracking. This ensures consistent product excellence across all production batches through systematic quality monitoring and comprehensive audit documentation.

- Comprehensive quality standard definition and categorization

- matic quality check logging with date and result tracking

- Detailed audit trail maintenance for compliance and reference

- Batch-wide quality consistency monitoring and reporting

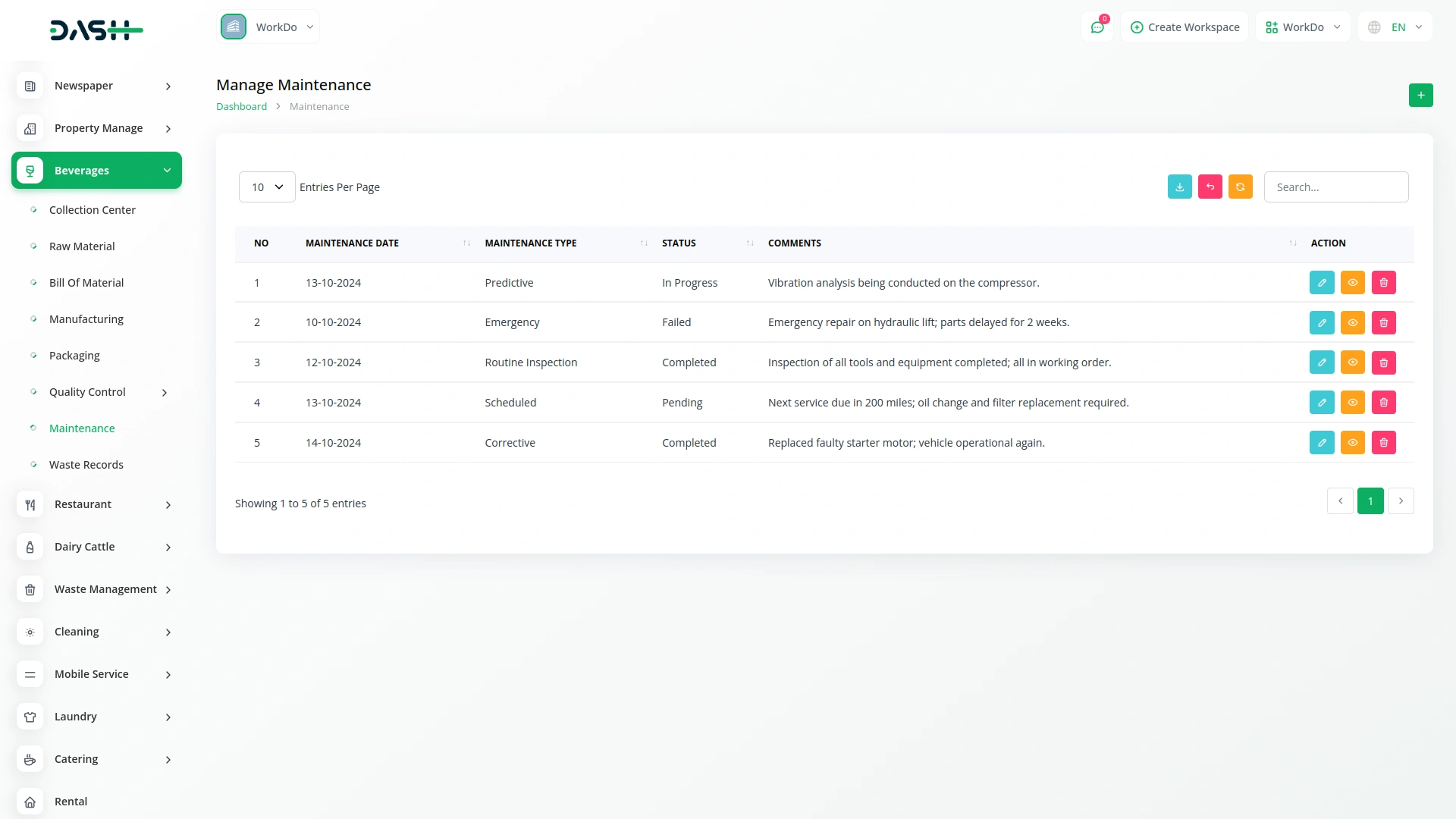

Maintenance Management

Maintain optimal equipment performance through comprehensive maintenance activity recording and systematic monitoring with detailed scheduling capabilities. The system tracks maintenance types, scheduled dates, current status, and technician commentary ensuring proactive equipment management and minimized operational downtime. Advanced features include maintenance scheduling optimization, detailed activity documentation, and performance reliability enhancement through systematic upkeep protocols.

- Comprehensive maintenance scheduling with type categorization

- Detailed technician activity recording and commentary tracking

- Equipment reliability optimization and performance enhancement

- Systematic downtime reduction through proactive maintenance

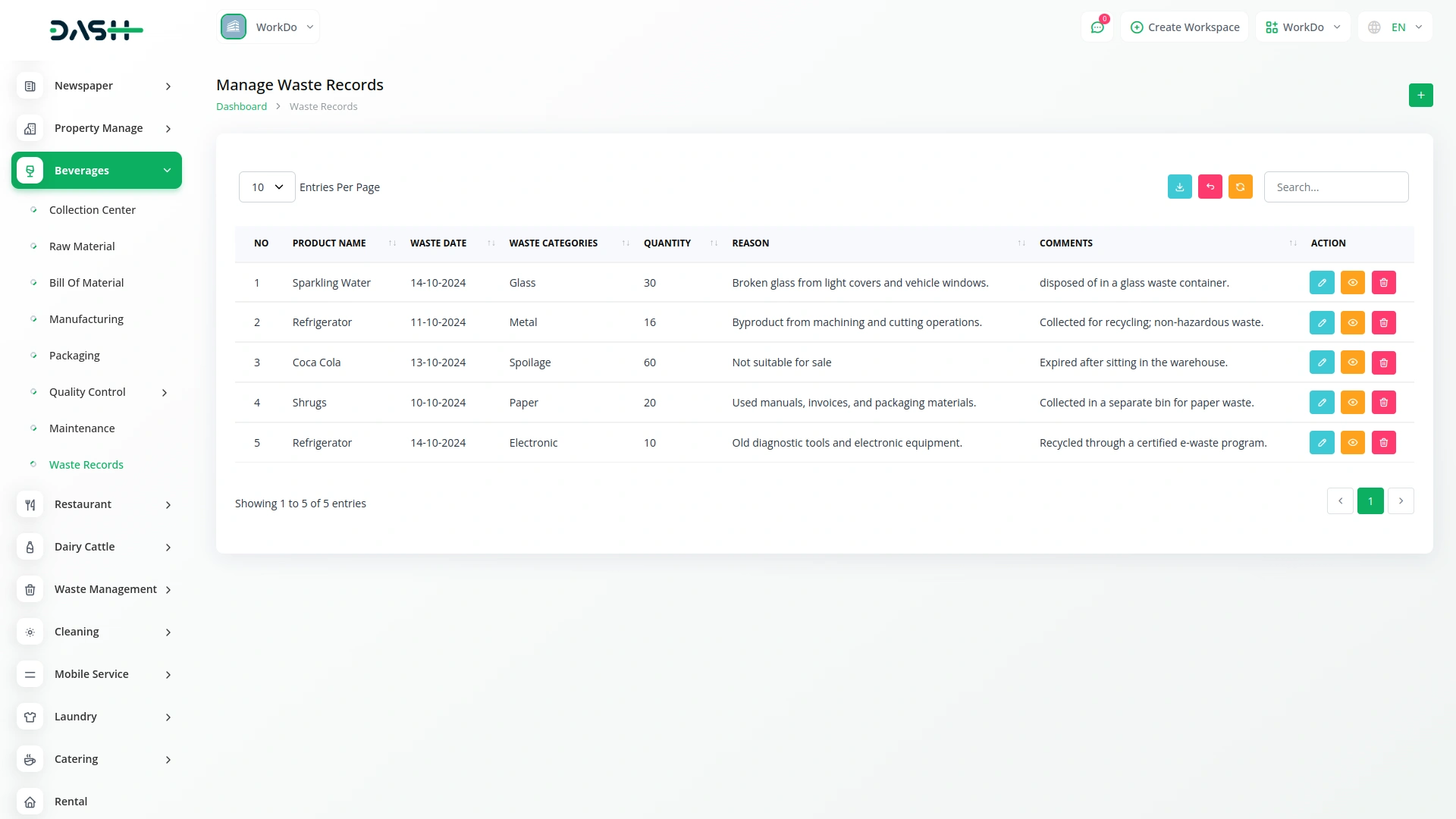

Waste Records

Optimize production efficiency through systematic waste recording and comprehensive analysis capabilities that track waste entries by product, date, category, quantity, and causation factors. The system enables detailed waste categorization for enhanced analytical insights while facilitating process optimization to minimize recurring waste patterns and operational losses. Advanced analytics help identify inefficiencies and implement corrective measures for continuous improvement.

- Comprehensive waste logging by product, quantity, and category classification

- Advanced waste type categorization for analytical insights

- Process optimization tools for recurring waste reduction

- Systematic loss analysis and efficiency improvement protocols

Screenshots from our system

To explore the functionality and usage of these Add-Ons, refer to the accompanying screenshots for step-by-step instructions on how to maximize their features.

6 reviews for Beverages Production System – Dash SaaS Add-On

| 5 star | 66% | |

| 4 star | 33% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Comments

You must be logged in to post a comment.

There are no comment yet.

Contact Us for Support :

-

You will get immediate support from our support desk. Please visit here https://support.workdo.io/

Item support includes:

- Answer pre-sale questions or query

- Answering technical questions about item's features

- Assistance with reported bugs and issues

- Help with included 3rd party assets

- Free Installation services in some cases

However, item support does not include:

- Customization services

Check Documents & Tutorials

Features are always relevant

Documentation saves a lot of training time

Even with a large volume of data, the add-on runs smoothly ensuring that our production line operates efficiently without lag.

It’s the ideal solution for beverage manufacturers. The system covers everything, from inventory management to production tracking and order fulfillment.

This add-on has completely streamlined our production process, allowing us to track everything from raw materials to finished goods effortlessly.

Flexibility